Ford Motor Company announced this morning that it is making a $5 billion bet on its electric vehicle future. The payout is a $30,000 midsize electric pickup truck arriving as soon as 2027. The investment involves overhauling its Kentucky and Michigan assembly and battery plants, reinventing the assembly line and developing a new Ford Universal EV Platform that will underpin the next generation of affordable electric vehicles of all shapes, sizes and scales.

The $30K electric truck

Let’s start with the most relevant bit. At an event at Ford’s Louisville Assembly Plant in Kentucky, Ford President and CEO Jim Farley announced that its next new vehicle would be an affordable, midsize electric pickup truck targeting a starting price of $30,000.

The yet-unnamed EV is said to boast “more passenger space than the Toyota RAV4.” Its F-150 Lightning-like front trunk (or “frunk”) and cargo bed grant it “tons of room for five adults, bikes, surfboards, work equipment, whatever you need, it’s all in the vehicle,” according to Farley. Ford also says the pickup will be “faster than the Ford Mustang twin-turbo,” which sprints to 60 mph in under 5 seconds.

Farley went on to state that the new truck will support fast charging, boast “amazing range,” and be able to power a house for up to six days thanks to its bidirectional charging capabilities. Ford claims it will support over-the-air updates and a full suite of tech and creature comforts for the $30,000 sans incentives — perhaps a dig at the recently announced Slate EV truck, a barebones electric pickup that targeted an incentive-dependent $20,000 net.

The cheapest electric cars of 2025

Ford Universal EV Platform

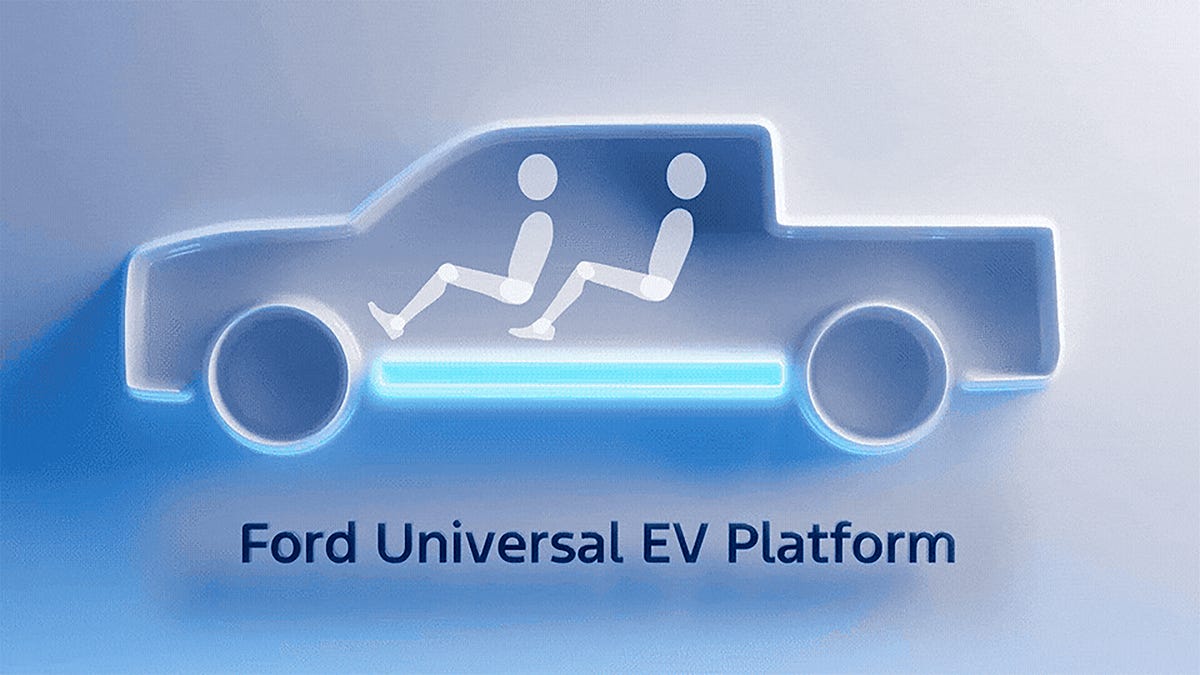

The new electric pickup will be the first vehicle built on the newly announced Ford Universal EV Platform, which will eventually underpin a family of affordable electric cars, trucks and SUVs. The new platform was designed for faster, simpler assembly (which would keep manufacturing costs down) and low, easy maintenance (which would reduce ownership costs).

Ford tells us that its newest EV will use 25% fewer fasteners than its previous, more conventionally built EVs. and that there will be 20% fewer parts overall thanks to smarter decision-making during the design and development stages. Zonal architecture enables the electrical systems to save around 10 kg of wire harness — not unlike what we’ve seen Rivian doing with its updated R1T and R1S.

Rethinking and simplifying how the car comes together, Ford estimates that the new EV truck can be assembled 15% faster than, say, a Mustang Mach-E electric SUV. Its simpler construction will presumably result in lower ownership costs over five years than “a three-year-old used Tesla Model Y,” which is a strangely specific comparison. But making EVs cheaper to maintain would be a win.

The Assembly Tree

Anyone familiar with American history knows how Ford revolutionized modern manufacturing with the Model T’s assembly line over 100 years ago. With its new Universal EV Platform, the automaker is again rethinking how it builds cars, evolving its assembly line into an assembly tree.

Vehicles based on the Universal EV Platform — starting with this new truck — will now be built in three parts on three parallel assembly branches: the front, the rear and the structural battery sub-assemblies. Once completed, these sub-assemblies will be mated on a trunk line where final assembly takes place.

Branched assembly lines aren’t exactly a novel idea. I recently visited Hyundai’s Singapore Innovation Center, where similar ideas are being tested. However, this is the first time I’ve seen a passenger car built in three discrete parts that snap together like Lego, and I’m interested to see how this construction technique plays out for long-term vehicle reliability.

Ford says that this, along with the simplifications of the Universal EV Platform, has the potential to reduce vehicle assembly times by up to 40% as it ramps up automation in the future. I can see how this could enable a ton of flexibility for building vehicles with multiple powertrain configurations (front, rear or all-wheel drive) or body configurations (pickups and SUVs) in the same facility.

$5 Billion Bet

To make all of this happen, Ford Motor Company is investing a total of $5 billion into the development of the new platform and vehicles and into its manufacturing facilities, with $2 billion going toward overhauling its Louisville Assembly Plant, where the new electric truck will be built. The rest will be split between research and development and Ford’s BlueOval Battery Park Plant in Michigan, where the automaker claims the first US-manufactured prismatic lithium iron phosphate (LFP) batteries will be built. The LFP batteries are said to be smaller and lighter than Ford’s current lithium-ion technology and require no expensive cobalt or nickel in their construction.

Ford’s high-stakes electric bet comes at a time when the deck seems stacked against the future of electric vehicles in the US. The policies of the current federal administration, which most recently included the elimination of EV incentives for customers, have seemed downright hostile toward electric cars and green energy.

“It is a bet. There is risk,” Farley said during today’s announcement stream. “The automotive industry has a graveyard littered with affordable vehicles that were launched in our country with all good intentions… At Ford, we set out to break that cycle. No more compliance cars. No more loss-leaders. We’re talking about a vehicle that can sustain itself, have strong profits, so all of our workers have an actually sustainable future.”

Read the full article here